global power

Agile Global Sourcing

With state-of-the-art facilities in five production centers across China and Southeast Asia and now Guatemala and Egypt, Seduno Group NY offers agile manufacturing options for all of your cut-and-sew knitwear needs.

Main Production Campus Ningbo China

Seduno Group NY: Your Gateway to Manufacturing Freedom

Our strategic investments in multiple manufacturing sites across diverse

locations empower our customers with unparalleled flexibility. Our strategic

planning now includes the planning and execution of a comprehensive vertical

near-shoring manufacturing operation in Mexico. This combination of factories

and locations affords you the freedom to tailor order sizes, select country of

origin to manage duties, fine-tune production schedules, and streamline delivery,

all with ease.

Complementing our company-operated factory complexes is an expansive

network of trusted suppliers spanning the globe. This collective strength makes

Seduno your ultimate "one-stop shop" for integrated apparel production.

Complementing our company-operated factory complexes is an expansive network of trusted suppliers spanning the globe. This collective strength makes Seduno your ultimate "one-stop shop" for seamless, integrated apparel production.

EXPERIENCE THE SEDUNO ADVANTAGE IN SOUTHEAST ASIA

One of the key strategic advantages we provide is the vertical integration of our state of the art cotton fabric mill located on our Vietnam production campus together with our expansive sewing plant capacity next door in Cambodia.

Since the inception of our fabric mill in Vietnam in 2018, renowned for its quality, size and capacity - knit production has skyrocketed from a mere 5 tons per day to an astounding 90 tons, marking an 1800% surge in just three years.

The strategic location of this mill, 20 minutes from the Cambodian border, has revolutionized order lead times. What once took up to 28 days for fabric delivery from China now reaches our Cambodia production plant in a very swift 6 hours.

As for our Vietnam apparel factory, the fabric is literally next door. This translates into one simple promise: your orders, delivered promptly, every time.

ELEVATING EXCELLENCE IN EVERY STEP:

Our merchandising, product development and production teams operate in harmony, fostering open communication, transparency, and integration at every juncture. We've incorporated 6 Sigma techniques into our management process,

ensuring that every individual involved in crafting your product comprehends your vision and consistently surpasses your expectations.

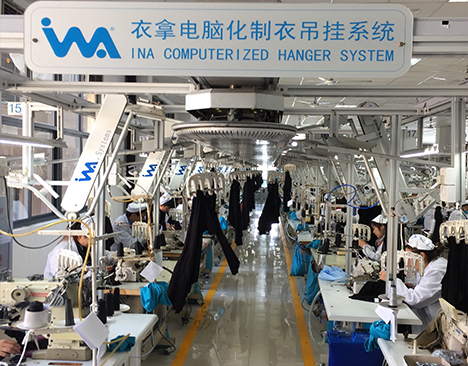

Our real-time computerized tracking and overhead hanging systems move products between stages flawlessly, ensuring consistent quality and precise scheduling.

At Seduno, our commitment to exceptional quality begins with a meticulous 10-point inspection of all our fabrics. Before cutting, we allow them to relax for a full 24 hours. Our production benefits from the efficiency and safety of computerized

Gerber Cutters, enhancing both output and worker safety.

Our dedication is evident in our remarkable monthly output, 6 million garments, all delivered with an exceptional 99.8% on-time record.

Please click here for a video profile of our company’s operations